A handmade tradition

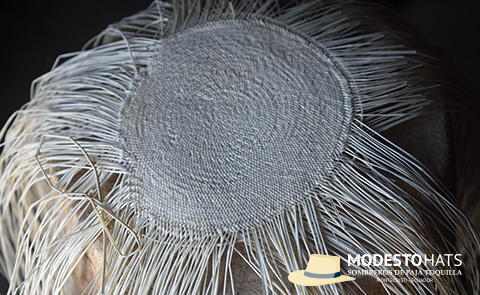

The Toquilla straw hat, despite the name Panama, has been a hat, appreciated by many people, and actors, it has always been woven in Ecuador, Montecristi, more than 400 years ago, a craft, made by skilled hands, Montecristense, back in the year 1916, there were several presidents around the world, among them “Theodore Roosevelt”, they gave him a hat, and from that moment on, it was known as a panama hat, the art of weaving toquilla straw hats. has passed from generation to generation, Panama hats are made of a straw, which comes from the palm leaf, cardulovica palmata, also known as straw toquilla, which grows in tropical climates, on the Ecuadorian coast, which They are located, behind the Montecristi hill, The collogos cook them, for a time of 8 to 10 minutes, to obtain the fibers, which are dried in the environment, then the best fibers are selected, to weave the finest hats in the world , They are made completely by hand, from their beginning to their final finish, this depending on the fineness, which each artisan will make, from 5 days to 8 months, the finest fibers are used, to obtain the best quality, in Montecristi Don Simón Espinal from the community, “Pile” is the best artisan, his hats cost hundreds of thousands of dollars.